In-house Electronics Manufacturing

At Emvexis, we don’t just design electronics; we build them too. Our in-house manufacturing capability gives us complete control over quality, flexibility, and schedule. Whether you need prototype runs, small-to-medium batch production, or specialist builds, we ensure the same rigorous standards at every stage.

Read on to find out more.

Why In-House Matters

Total quality control – Every assembly is built directly under our control from stencil to final inspection, with component level traceability.

Rapid turnaround – No waiting on external subcontractors; design changes and iterations can be implemented immediately.

Flexibility – From one-off prototypes to production batches, we scale to match your requirements.

Our Plant List

Our facility is fully equipped for modern PCBA assembly, inspection, and testing:

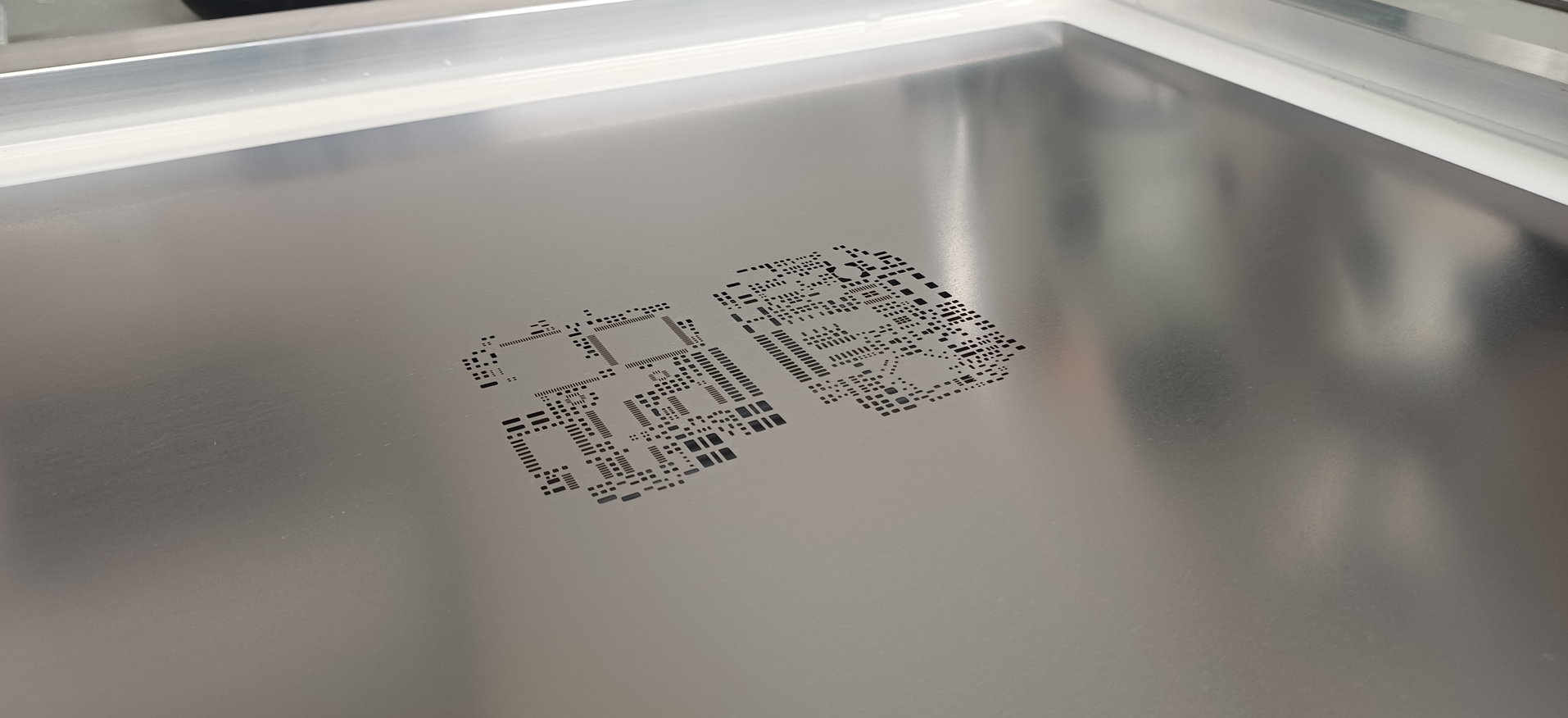

Guided stencil printer – For precise solder paste application and repeatable quality.

Pick and place machine – Automated placement of SMD components with high accuracy and throughput, component placement down to 0201 size

Vacuum drying oven – For drying of MSL rated (moisture-sensitive) devices and process reliability.

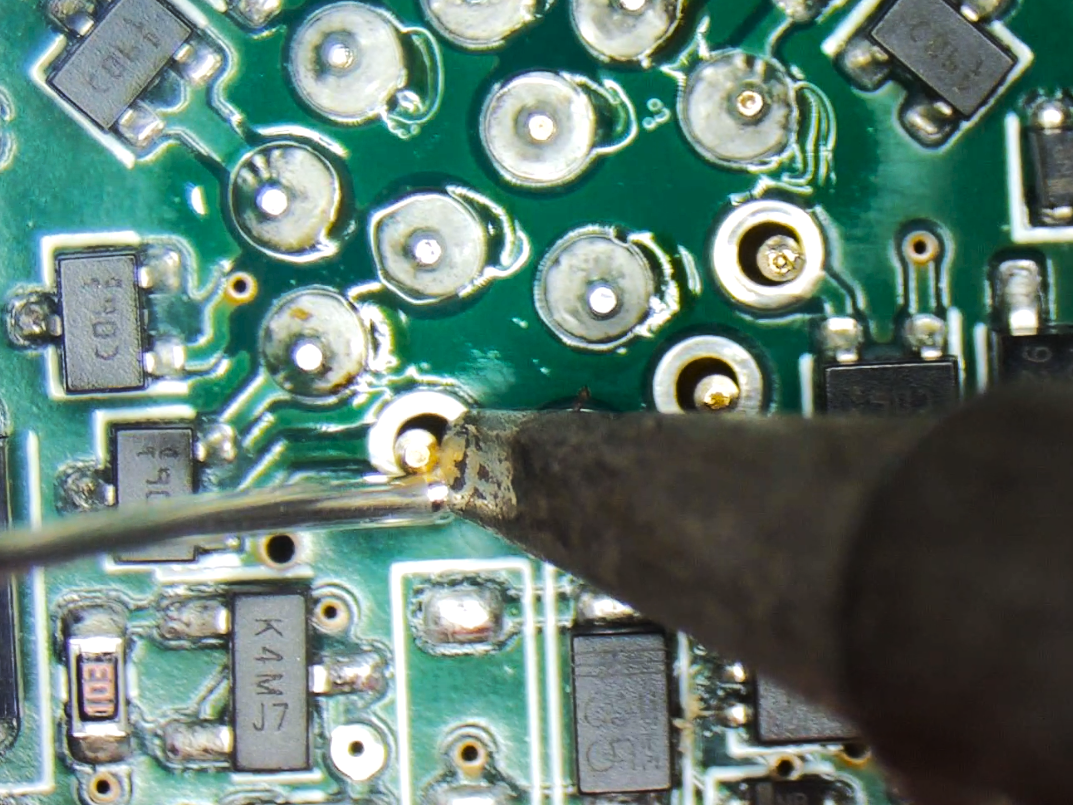

Analog and digital microscopes – For inspection, verification, and fine rework, up to 90x magnification + digital video and image capture

Reflow soldering – Controlled thermal profiles for reliable SMD solder joints.

Solder paste refrigeration – Cold storage of solder pastes to manufacturer specifications.

Hot air rework – For repair, rework, and modifications to complex assemblies.

Static controls – ESD-safe flooring, benches, and procedures protect sensitive devices.

Fume extraction, filtering, and recirculation – Ensuring a clean, safe working environment.

Test and measurement equipment – Oscilloscopes, DMMs, function generators, programmable power supplies, and more for verification and debug.

ESD-safe hand tooling – Precision soldering stations, cutters, tweezers, and assembly tools designed for electronics manufacturing.